Tool Room

City skyline

Tool Room

Omni maintains a 24,000 square foot facility dedicated to designing, building and maintaining production tools. Many conventional tools such as mills, drills, grinders, heat-treat equipment, welders, and more are housed in this facility.

Our Tool Room facility currently has two wire EDM machines, complete with CAD/CAM interface. Also, there are four large machining centers with CAD/CAM interface, too. These tools immensely reduce the amount of time necessary to develop and construct any tooling project.

Our Technical Facilities office is fully equipped with state-of-the-art CAD/CAM computer systems, utilizing the latest versions of SOLIDWORKS, Logopress3 die design software, FTI Fast Incremental Simulation Software and Edgecam. These systems allow Omni personnel to translate data files of all types, enabling the staff to work hand-in-hand with client engineering departments. Additionally, this equipment helps our ability to manufacture transfer tooling, progressive tooling and more. Data produced with these systems is capable of being transferred via network connections directly to machine tools located in the shop. Again, these tools allow Omni to greatly reduce the time required to develop and build tooling projects.

Omni Manufacturing invests a vast amount of resources to ensure that our tooling facility is equipped with the necessary equipment and a highly qualified staff.

Our Capabilities

Stamping

Omni’s production facility houses over 75 metal stamping presses and the necessary support equipment. Our presses range in size from 50 tons to 1500 tons.

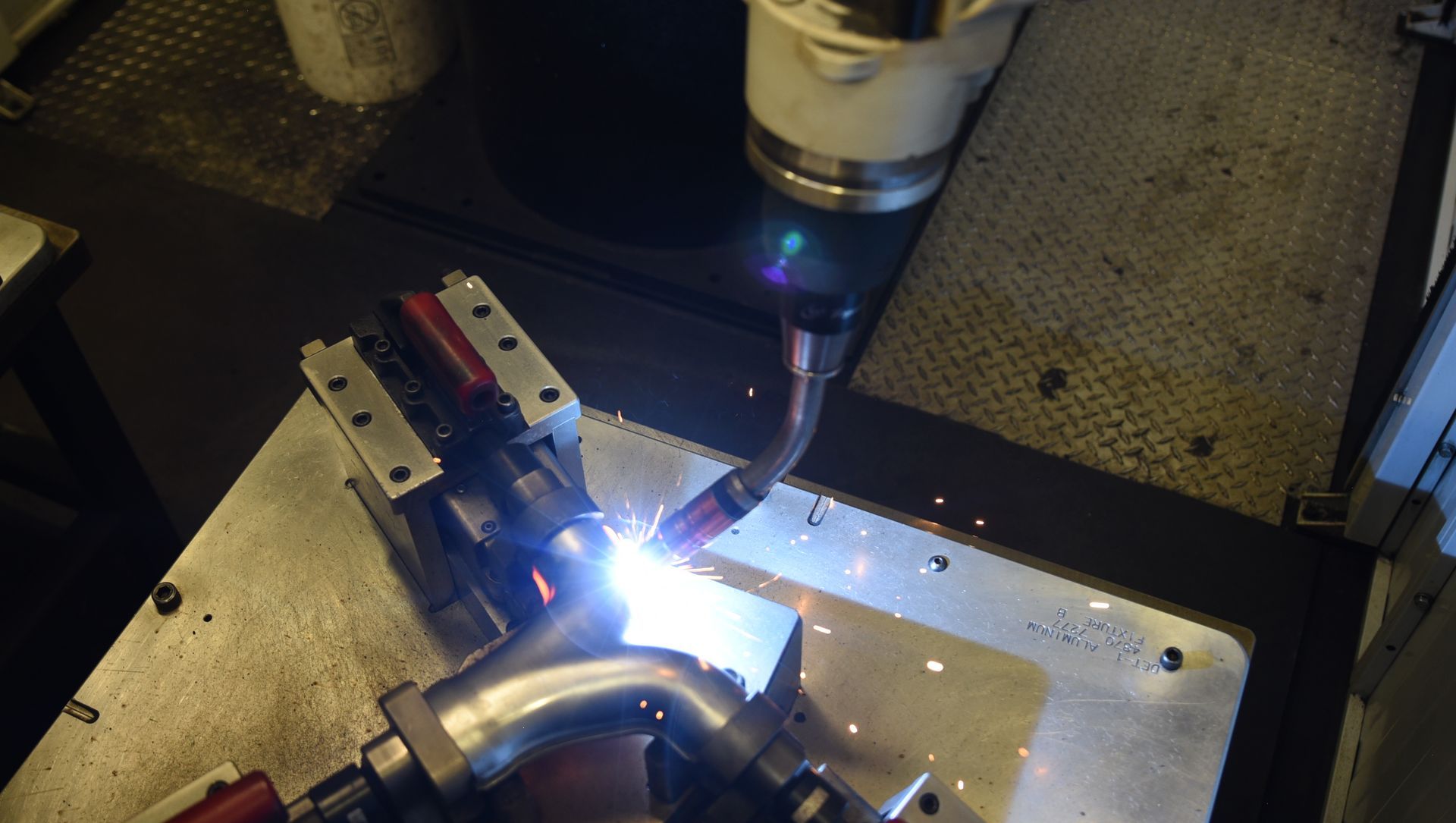

Welding

We have numerous robotic weld cells, each capable of handling multiple weld operations in a production environment.