Careers

We are waiting for you!

Become a part of our team here at Omni and unlock a world of fantastic opportunities! We take pride in providing our employees with competitive pay, exceptional benefits, and the luxury of paid holidays. Join us now and embark on a journey of professional growth and fulfillment.

At Omni, we offer a wide variety of different departments, each contributing to our dynamic and diverse work culture. Whether you're a seasoned expert or a fresh talent, we have the perfect spot for you to thrive. Our collaborative environment fosters innovation, creativity, and teamwork, making it an ideal place to bring your ideas to life.

Join our family at Omni and be part of a community that values its employees and supports their personal and professional development. We look forward to welcoming you aboard!

Job Descriptions

Thank you for your interest in Omni Manufacturing. Please be aware that while we have a variety of positions listed, as these are job descriptions. Not all positions may be available at this time.

-

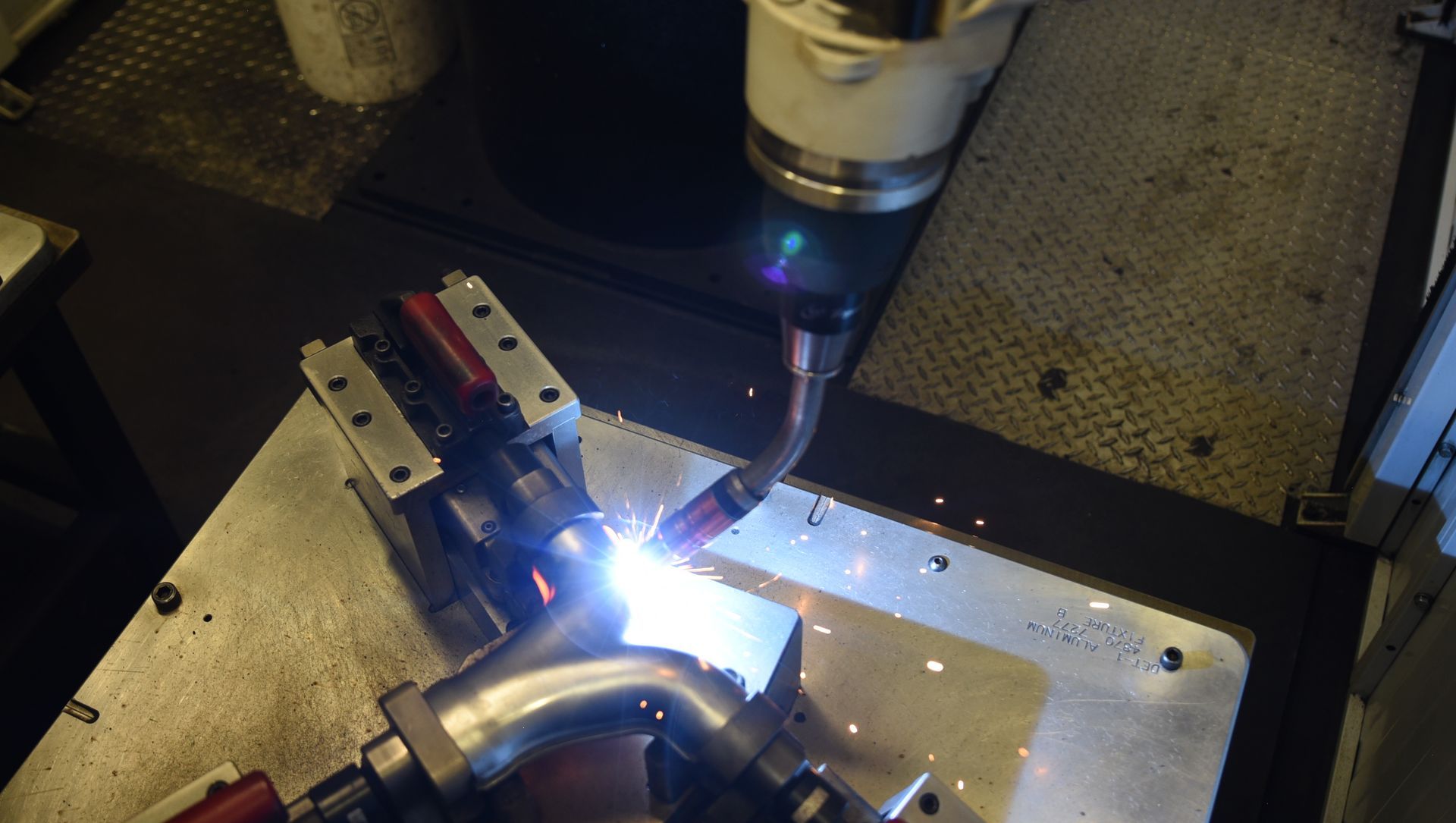

Robotic Welder

- READ AND UNDERSTAND BLUEPRINTS

- PRODUCE A WELDED PART WHICH TESTS IN ACCORDANCE WITH PRINT AND/OR PROCESS

- PERFORM BASIC MATH SKILLS

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- STAND FOR AN ENTIRE SHIFT

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- ADJUST AIR PRESSURES

- ADJUST HEAT TEMPERATURES

- ADJUST TIP CLEARANCES

- ADHERE TO ALL OMNI POLICIES, PROCEDURES & INSTRUCTIONS

- MAINTAIN ATTENDANCE

- POSESS KNOWLEDGE OF A MANUFACTURING ENVIRONMENT

- WORK IN EXTREME TEMPERATURES

- PERFORM MINOR PROGRAMMING OF THE ROBOT'S COMPUTER

- POSSESS STRONG WELDING BACKGROUND

- OPERATE MOTOMAN ROBOITC WELDER

- OPERATE STS WELDER

- OPERATE A FORKLIFT

- WORK IN A GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

-

Safety Director

- SUPPORT VICE PRESIDENT IN DAILY OPERATIONS OF COMPANY

- ASSIST IN IMPLEMENTATION AND MONITORING OF APPLICABLE SAFETY STANDARDS

- DEVELOP EMPLOYEE SAFETY TRAINING

- CONDUCT EMPLOYEE SAFETY TRAININGS

- MAINTAIN MATERIAL SAFETY DATA BOOKS

- MAINTAIN EMPLOYEE SAFETY RECORDS

- MAINTAIN AND UPDATE MAINTENANCE DATABASE

- MAINTAIN PREVENTATIVE MAINTENANCE WORK ORDERS

- PROCURE NECESSARY PRODUCTION LUBRICANTS AND SUPPLIES

- PROCURE REQUIRED SAFETY ITEMS

-

Sales/Marketing Manager

- DEVELOP SALES GOALS AND STRATEGIES TO ACHIEVE OMNI MANUFACTURING GOALS

- CREATE/CARRY OUT PLANS TO DEVELOP NEW MARKETS

- IDENTIFY/DEVELOP NEW CUSTOMER BASE

- SERVES AS COMPANY CUSTOMER SERVICE REPRESENTATIVE

- FORMULATE PLANS TO RESOLVE CUSTOMER ISSUES

- RESOLVE CUSTOMER COMPLAINTS

- NEGOTIATE CONTRACTS WITH CUSTOMERS

- SERVES AS LIAISON BETWEEN CUSTOMERS AND OMNI MANUFACTURING STAFF

- ANALYZE COSTS -VS- SALE PRICE AND MAKE ADJUSTMENTS ACCORDINGLY

- ANALYZE EFFICIENCY OF PRODUCTION

-

Die Setter -Set Up Personnel

- READ AND UNDERSTAND BLUEPRINTS

- CHANGEOVER DIES AND FIXUTRES IN EQUIPMENT

- PERFORM BASIC MATH SKILLS

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- STAND FOR AN ENTIRE SHIFT

-

Office Assistant/Shipping

- PERFORM BASIC MATH SKILLS

- ISSUE SHOP PACKETS TO JOBS

- PREPARE PURCHASE ORDERS

- PREPARE SHIPPING DOCUMENTS

- PREPARE REPORTS

- INITIATE JOB ROUTINGS

- TRACK PURCHASE ORDERS AND ACKNOWLEDGEMENTS

- MAINTAIN DATABASE TRACKING JOB ROUTINGS AND INVENTORY OF PARTS

- COORDINATES PRODUCT SHIPMENTS WITH TRUCKING COMPANIES

- ANSWER TELEPHONE QUERIES CONCERNING SHIPMENTS

-

Tool Room Manager/Tool Designer

- DESIGN TOOLS UTILIZED BY OMNI MANUFACTURING

- DESIGN JIGS, FIXTURES, AND SPECIAL

MACHINERY AS NEEDED - MANAGE PROCESS OF DESIGN FROM INCEPTION INTO PRODUCTION

- SCHEDULE WORKLOAD AS NECESSARY TO ENSURE COMPANY'S GOALS ARE MET

- ENSURE COST-EFFECTIVE & EFFICIENT METHODS ARE USED TO ACHIEVE GOALS

- PROCURE EQUIPMENT REQUIRED TO ACHIEVE FINISHED PRODUCT

BE SELF-MOTIVATED

PROGRAM CNC EQUIPMENT

ATTEND COMPANY & CUSTOMER MEETINGS

IDENTIFY NECESSARY LABOR CHANGES/NOTIFY HR BEFORE IMPLEMENTING

SCHEDULE EMPLOYEES TO ENSURE COMPANY'S GOALS ARE MET

-

Production Spot Welder

- READ & UNDERSTAND BLUEPRINT / SHOP DRAWINGS

- PRODUCE A WELDED PART WHICH TESTS IN ACCORDANCE WITH PRINT AND /OR PROCESS SHEETS

- PERFORM BASIC MATH SKILLS

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORKAREA

- MAINTAIN ATTENDANCE

- STAND FOR AN ENTIRE SHIFT

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- ADHERE TO ALL OMNI POLICIES, PROCEDURES, & INSTRUCTIONS

POSSESS KNOWLEDGE OF A MANUFACTURING ENVIRONMENT

WORK IN EXTREME TEMPERATURES

OPERATE SAME WELDER SEVERAL DAYS IN A ROW

OPERATE A VARIETY OF WELDERS IN ONE DAY

WORK IN A GREASY OR DIRTY ENVIRONMENT

WORK IN A LOUD ENVIRONMENT

UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

KEEP WORK AREA CLEAN

-

Quality Engineer

- PRODUCE INSPECTION AND CMM LAYOUT REPORTS

- AID IN SCRAP ANALYSIS AND SCRAP REDUCTION

- PERFORM TROUBLE SHOOTING AND ANALYSIS

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- SOLVE QUALITY PROBLEMS

- STAND FOR LONG PERIODS OF TIME

-

Quality Assurance Manager

- IMPLEMENT/MAINTAIN OMNI MANUFACTURING QUALITY SYSTEM IAW ISO O9001/QS 9000

- ESTABLISH NEW QUALITY PROCEDURES FOR PROCESSES AS REQUIRED

- IDENTIFY/REPORT THE PERFORMANCE OF THE QUALITY SYSTEM TO MANAGEMENT

- RECOMMEND IMPROVEMENTS TO THE QUALITY SYSTEM AS REQUIRED

- SERVE AS CUSTOMER CONTACT ON MATTERS RELATING TO QUALITY OF COMPANY'S

- INITIATE ACTION NECESSARY TO PREVENT NON-CONFORMANCE RELATING TO ALL

- REPORT/VERIFY IMPLEMENTATION OF SOLUTIONS

-

Quality Technician

- READ AND UNDERSTAND BLUEPRINTS INCLUDING GD&T

- CREATE DOCUMENTS

- ASSIST MANAGER IN QS 9000 DOCUMENTATION

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- SOLVE QUALITY PROBLEMS

- STAND FOR LONG PERIODS OF TIME IN PLANT

-

Receptionist

- ANSWER INCOMING CALLS PROFESSIONALLY USING A MULTI-LINE PHONE SYSTEM

- DIRECT MESSAGES TO PROPER PARTY, TAKE MESSAGES AND/OR DIRECT MESSAGES TO VOICEMAIL

- GREET VISITORS AND GUESTS

- TYPE REPORTS AND CORRESPONDENCE

- FORWARD MESSAGES IN A TIMELY MANNER

- PERFORM DATA ENTRY

- PERFORM OTHER DUTIES AS ASSIGNED

- POSSESS ABILITY TO WORK AS A TEAM MEMBER

- SORT AND DISTRIBUTE MAIL

- SUPPORT PRODUCTION

- SUPPORT SALES

- SUPPORT HR

- SUPPORT QUALITY

- LOG AND FILE LOADING TALLY SHEETS

- ASSIST WITH BUSINESS CORRESPONDENCE

- ASSIST WITH MISCELLANEOUS FILING

- POSSESS EXCELLENT COMMUNICATION AND INTERPERSONAL SKILLS

- SIT FOR LONG PERIODS OF TIME

-

Maintenance Supervisor

- SCHEDULE MAINTENANCE PERSONNEL

- SCHEDULE MAINTENANCE TASKS

- RESPONSIBLE FOR PRODUCTION EFFICIENCY IN DEPARTMENT

- ASSESS OVERALL OPERATION TO DETERMINE MAINTENANCE REQUIREMENTS

- DEVELOP/CONDUCT TRAINING OF MAINTENANCE PERSONNEL

- CONDUCT ORIENTATION OF NEW MAINTENANCE EMPLOYEES

- CONDUCT DISCIPLINARY ACTIONS OF MAINTENANCE EMPLOYEES

IDENTIFY LABOR CHANGES REQUIRED/NOTIFY HR BEFORE IMPLEMENTING CHANGE

PARTICIPATE IN SAFETY GROUPS

PERFORM ELECTRICAL/ELECTRICAL 3/PHASE TROUBLESHOOTING

RESPONSIBLE FOR REPAIR IDENTIFIED EQUIPMENT DURING TROUBLESHOOTING

-

Maintenance Technician

- SCHEDULE MAINTENANCE PERSONNEL

- SCHEDULE MAINTENANCE TASKS

- RESPONSIBLE FOR PRODUCTION EFFICIENCY IN DEPARTMENT

- ASSESS OVERALL OPERATION TO DETERMINE MAINTENANCE REQUIREMENTS

- DEVELOP/CONDUCT TRAINING OF MAINTENANCE PERSONNEL

- CONDUCT ORIENTATION OF NEW MAINTENANCE EMPLOYEES

- CONDUCT DISCIPLINARY ACTIONS OF MAINTENANCE EMPLOYEES

- IDENTIFY LABOR CHANGES REQUIRED/NOTIFY HR BEFORE IMPLEMENTING CHANGE

- PARTICIPATE IN SAFETY GROUPS

- PERFORM ELECTRICAL/ELECTRICAL 3/PHASE TROUBLESHOOTING

- RESPONSIBLE FOR REPAIR IDENTIFIED EQUIPMENT DURING TROUBLESHOOTING

-

Manufacturing Manager

- SUPERVISE PLANT PERSONNEL

- SCHEDULE PRODUCTION

- NEGOTIATE PRICING WITH SUPPLIERS FOR RAW MATERIALS

- SCHEDULE DELIVERY OF RAW MATERIALS

- SCHEDULE SHIPPING OF FINISHED PRODUCT

- APPROVE USE OF SUB-CONTRACTORS WHEN NECESSARY

- POSSESS BACHELORS DEGREE

- POSSESS 5 YEARS EXPERIENCE IN MATERIAL MANAGEMENT

- POSSESS WORKING KNOWLEDGE OF MANUFACTURING ENVIRONMENT

- ANSWER TELEPHONE QUERIES CONCERNING SHIPMENTS

-

PC 3 & 4 Supervisor

- READ AND UNDERSTAND BLUEPRINTS AND PROCESS DRAWINGS

- SCHEDULE PRODCUTION ASSOCIATES

- PERFORM BASIC MATH SKILLS

- CORRECTLY OPERATE MEASURING DEVICES

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- STAND FOR AN ENTIRE SHIFT

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- OPERATE A PRESS

- OPERATE INFARED OVENS

- OPERATE BOILERS

- OPERATE RIVET MACHINE

- OPERATE A SPOT WELDER

- OPERATE BRAKES

- OPERATE OVENS

- OPERATE HAND AND AUTO PAINT EQUIPMENT

- OPERATE WATER BALANCE EQUIPMENT

- OPERATE OVEN MONITOR DEVICES

- OPERATE BAR CODE EQUIPMENT

- WORK WITH CHEMICALS

- WORK IN EXTREME TEMPERATURES

- WORK IN A GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- MAINTAIN PRODUCTION EFFICIENCIES IN DEPARTMENT

- MAINTAIN QUALITY PRODUCTS WITHIN DEPARTMENT

- ENFORCE ALL COMPANY POLICIES AND PROCEDURES

- OVERSEE TRAINING AND DIRECTION OF PRODUCTION ASSOCIATES

- CONDUCT EMPLOYEE INVOLVEMENT MEETINGS

- PERFORM LINE INSPECTION TESTS DURING EACH SHIFT

- WRITE WORK ORDERS

- COORDINATE WORK ORDERS

- ISSUE DISCIPLINARY ACTION WHEN NECESSARY

- ORIENTATE NEW EMPLOYEES

- NOTIFY HR PRIOR TO IMPLEMENTATION OF LABOR CHANGE

- APPROVE COMPLETED LABOR TRANSACTIONS

- APPROVE TIME SHEETS

- WORK TO ACHIEVE COMPANY GOALS

- PROMOTE COST EFFECTIVENESS

- PROMOTE OPERATIONAL EFFICIENCY AMONG ASSIGNED EMPLOYEES

- POSSESS ASSOCIATES DEGREE, CERTIFICATE IN MANAGEMENT OR EQUIVALENT

- BACKGROUND EXPERIENCE

- POSSESS 2-3 YEARS EXPERIENCE IN PRODUCTION MANAGEMENT

- POSSESS BACKGROUND IN WELDING

- POSSESS BACKGROUND IN STAMPING

- POSSESS BACKGROUND IN NYLON AND POWDER COATING OF PRODUCTS IN AUTO-

- MOTIVE, APPLIANCE AND HOME HARDWARE INDUSTRIES

- POSSESS AND DEMONSTRATE THE ABILITY TO FOLLOW INSTRUCTIONS

- MAINTAIN PATIENCE AND TACT IN DEALING WITH OUTSIDE PATRONS AND FELLOW EMPLOYEES

- ORGANIZE TIME

- EVALUATE PRIORITIES

- COMPLETE TASKS UNDER DEADLINE

- POSESS STRONG COMMUNICATION AND TEAMWORK SKILLS

- ADHERE TO ALL OMNI MANUFACTURING, INC. COMPANY POLICIES

-

Pivot Bracket Assembler

- CHECK PARTS TO INSURE THEY COMPLY WITH PRINT TOLERANCES, COLOR AND SURFACE SPECIFICATIONS

- PERFORM BASIC MATH SKILLS

- PLACE PIVOTS AND GROMMETS INTO MACHINE

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- STAND FOR AN ENTIRE SHIFT

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- RIVOT PARTS TOGETHER

- REMOVE ASSEMBLED PARTS

- WING THE ASSEMBLED PARTS FOR PROPER TENSION

- LOAD PARTS INTO TOTES

- STACK TOTES ON SKID AND ATTACH BAR CODE TO EACH TOTE

- MAINTAIN ACCURATE INVENTORIES

- WORK IN EXTREME TEMPERATURES

- INSURE NECESSARY MOVE TAGS ARE PREPARED

- INSURE NECESSARY SHIPPING DOCUMENTS ARE PREPARED

- WORK IN A GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- KEEP WORK AREA CLEAN

- OPERATE GUAGES

- OPERATE RIVET MACHINE

- PERFORM PROPER STACKING OF TOTES ON SKIDS AND BAR CODE LABELING

-

Junior Tool Maker

- ASSIST SENIOR TOOLMAKER IN THE BUILDING OF SINGLE HIT, PROGRESSIVE, TRANSFER TOOLS, EQUIPMENT & PRODUCTION GAGES

- ASSIST SENIOR TOOLMAKERS IN THE BUILDING OF JIGS

- ASSIST SENIOR TOOLMAKERS IN THE BUILDING OF FIXTURES

- ASSIST SENIOR TOOLMAKERS IN THE BUILDING OF SPECIAL MACHINERY AS NECESSARY

- PERFORM FIRST PIECE APPROVAL OF TOOLS AND SPECIAL MACHINERY

- STAND FOR EXTENDED PERIODS OF TIME

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- PURCHASE & MAINTAIN PERSONAL TOOLS

- REPORT TO TOOLROOM MANAGER

- ASSIST SENIOR TOOLMAKERS IN THE DE-BUGGING OF TOOLS & SPECIAL MACHINERY

- PROGRAM CNC EQUIPMENT (MILLS, EDM'S, ETC.)

- MAINTAIN TOOLING & SPECIAL MACHINERY AS NECESSARY

- ATTEND & SUPPORT ALL MEETINGS & FUNCTIONS NECESSARY TO SUPPORT THE OPERATIONS OF OMNI MFG., INC.

-

Apprentice Tool Maker

- ASSIST SENIOR/JUNIOR TOOLMAKER IN THE BUILDING OF SINGLE HIT GAGES

- ASSIST IN THE BUILDING OF TRANSFER TOOLS

- ASSIST IN THE BUILDING OF JIGS

- ASSIST IN THE BUILDING OF FIXTURES

- ASSIST IN THE BUILDING OF SPECIAL MACHINERY AS NECESSARY

- PERFORM FIRST PIECE APPROVAL OF TOOLS AND SPECIAL MACHINERY

- STAND FOR EXTENDED PERIODS OF TIME

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- PURCHASE & MAINTAIN PERSONAL TOOLS

- REPORT TO TOOLROOM MANAGER

- ASSIST IN THE DE-BUGGING OF TOOLS & SPECIAL MACHINERY

- MAINTAIN TOOLING & SPECIAL MACHINERY AS NECESSARY

- ATTEND & SUPPORT ALL MEETINGS & FUNCTIONS NECESSARY TO SUPPORT THE OPERATIONS OF OMNI MFG., INC.

-

Controller

- SUPERVISE AND COORDINATE SUBORDINATES

- ADJUST SCHEDULES AND PROCEDURES IN ACCOUNTING DEPARTMENT

- COMPILE GENERAL LEDGER

- COMPILE FINANCIAL STATEMENTS

- ANALYZE ALL FINANCIAL INFORMATION TO EXTRACT NECESSARY DATA TO ENABLE EFFICIET OPERATION OF THE COMPANY

- ADVISE OTHER MANAGEMENT PERSONNEL ON FINANCIAL MATTERS

- POST INVOICES AND DEBIT MEMOS

- PAY INVOICES

- CONTROL RECEIVER

- HANDLE BANKING PROCEDURES

- POST BILLING AND PAYMENT INFORMATION

- WORK WITH JOB COSTING PROCEDURES - COST POSTING AND COST ANALYSIS

- POST JOURNAL ENTRIES

- HAVE KNOWLEDGE OF THE ACCOUNT NUMBER STRUCTURE

- WORK WITH FIXED ASSETS

- FOLLOW MONTHLY AND YEAR END CLOSING PROCEDURES

- CONTROL AND EVALUATE INVENTORY

- PREPARE ALL FINANCIAL STATEMENTS

- SIT FOR LONG PERIODS OF TIME

- HAVE GOOD FINGER AND HAND DEXTERITY

-

Document Control Clerk

- MAINTAIN DOCUMENTS ASSOCIATED WITH THE MANUFACTURING PROCESS

- PREPARE & MAINTAIN MANUFACTURING PROCESS INSTRUCTION BOOK TO INSURE THAT PROPER DOCUMENTATION IS AVAILABLE & USED

- PREPARE & MAINTAIN DOCUMENT CONTROL LOGS

- DOCUMENT REVISION LOGS AS REQUIRED

- ASSIST IN OTHER DOCUMENT PREPARATION IN THE QUALITY DEPARTMENT

- PERFORM DATA ENTRY

- PERFORM OTHER DUTIES AS ASSIGNED

- POSSESS ABILITY TO WORK AS A TEAM MEMBER

- WORK IN A LOUD ENVIRONMENT AT TIMES

- WORK IN A GREASY ENVIRONMENT AT TIMES

- POSSESS EXCELLENT COMMUNICATION AND INTERPERSONAL SKILLS

- SIT FOR LONG PERIODS OF TIME

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- HAVE VISUAL ACUITY AND ACCURACY

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

HAVE PATIENCE AND TACT IN DEALING WITH OUTSIDE PATRONS AND FELLOW EMPLOYEES

MAINTAIN ATTENDANCE

-

Facilities Maintenance

- CLEAN PRODUCTION AREAS

- MAINTAIN PRODUCTION AREAS

- ORGANIZE PRODUCTION AREAS

- CLEAN EQUIPMENT

- MAINTAIN EQUIPMENT

- ORGANIZE EQUIPMENT

- STAND FOR AN ENTIRE SHIFT

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- ASSIST WITH MOVEMENT OF EQUIPMENT AND TOOLS

- PROPERLY USE A BROOM

- PROPERLY USE A MOP

- PROPERLY USE CLEANING SOLUTIONS

- WORK IN EXTREME TEMPERATURES

-

Human Resource Manager

- SUPPORT PRESIDENT TO ENSURE EFFICIENCY OF OPERATION OF HIS/HER OFFICE

- FIELD TELEPHONE CALLS FOR PRESIDENT

- PROCESS PRESIDENT'S DAILY MAIL

- HANDLE PRESIDENT'S BUSINESS/PERSONNEL CORRESPONDENCE

- ORGANIZE/MAINTAIN PRESIDENT'S BUSINESS/PERSONAL FILES

- ASSIST PRESIDENT IN HIS/HER BUSINESS/PERSONAL AFFAIRS AS REQUESTED

- SUPERVISE RECEPTIONIST POSITION

- SUPPORT PAYROLL DEPARTMENT WHEN REQUIRED

- REVIEW ALL APPLICATIONS/RESUMES FOR PROSPECTIVE EMPLOYEES

-

Accounting/Payroll Clerk

- ASSIST WITH ACCOUNTS PAYABLE TRANSACTIONS/POST INVOICES & DEBIT MEMOS

- ASSIST IN ACCOUNT & BANK RECONCILLIATION

- PROCESS ACCOUNTS RECEIVABLE TRANSACTIONS

- ASSIST & POST JOURNAL ENTRIES & GENERAL LEDGER

- ASSIST IN REPORTING AND STATISTICAL GATHERING

- PROCESS PAYROLL INFORMATION & PREPARE PAYROLL CHECKS

- PREPARE LABOR PERFORMANCE REPORTS

- KEEP EMPLOYEE DEMOGRAPHIC & DEDUCTION INFORMATION CURRENT

- RESOLVE ANY CUSTOMER INVOICE DISCREPANCIES IN A TIMELY MANNER

- ASSIST EMPLOYEES IN UNDERSTANDING PAYROLL CALCULATION & DEDUCTIONS

- INVESTIGATE PROBLEMS & MAKE APPROPRIATE CORRECTIONS

- COMPILE STATISTICAL & ACCOUNTING INFORMATION FOR PAYROLL

- COMPLETE GOVERNMENTAL FILINGS FOR PAYROLL TAXES

- PROCESS CHECKS FOR PAYROLL DEDUCTIONS & TAX PAYMENTS

- POSSESS EXCELLENT COMMUNICATION AND INTERPERSONAL SKILLS

- SIT FOR LONG PERIODS OF TIME

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- HAVE VISUAL ACUITY AND ACCURACY

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

-

Jr. Press Operator

- READ AND UNDERSTAND BLUEPRINTS

- RUN THE DIFFERENT JOBS ASSOCIATED WITH PRESS OPERATION

- PERFORM BASIC MATH SKILLS

- CORRECTLY OPERATE MEASURING DEVICES

- Operator informed that he/she is to maintain a neat work area and put tools in proper place

- Operator informed that he/she may be required to stand for an entire shift

- Operator informed that he/she will be required to remain alert for an entire shift

- Operator informed that finger and hand dexterity are essential for the position

- Operator informed that he/she will perform repetitive tasks

- Operator demonstrated that he/she is proficient at performing the 2-hand control button check procedure

- Operator proficient at identifying and using the red color EMERGENCY STOP button

- Operator proficient at identifying and using the yellow color TOP STOP button

- Operator proficient at identifying and using the main motor start/stop

- Operator proficient at identifying and using the mode selector

- Operator demonstrated that he/she is proficient at performing the light curtain check procedure

- Operator informed about using tools, and not hands, to remove stuck work and/or obstructions from/in the die area

- Operator informed that he/she is not to circumvent or by-pass any of the safe-guard functions

- Operator informed and shown as to where possible pinch points are located

- Operator informed that he/she should report to his/her supervisor any apparent defect, damage, malfunction, or inconsistent or unpredictable performance of the press operation

- Operator demonstrated that he/she is proficient at performing a safety interlock check

- Operator demonstrated that he/she is proficient at performing a brake monitor check

- Operator demonstrated that he/she is proficient at performing a jamb block check

- Operator informed as to the operating procedures of a leveler

- Operator informed as to the operating procedures of a feeder

- Operator informed as to the operating procedures of a welder

- Operator informed as to the operating procedures of a reel

- Operator informed as to the operating procedures of the in-line parts washer

- Operator informed that he/she may be working in extreme temperatures

- Operator informed that he/she may be operating the same press for consecutive days

- Operator informed that he/she may be operating a variety of presses in one day

- Operator informed that he/she may be working in a greasy and/or dirty environment

- Operator informed that he/she will be working in a noisy environment

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- Operator informed that he/she may be asked to assist in starting coils and material

- Operator informed that he/she is required to adhere to all company policies and work rules

- Operator informed that operator pedestals are to be located outside the defined red line during press operations

- CHECK THE SET-UP OF MODE SELECTORS

- Operator demonstrated the he/she is proficient at performing the start-up procedures for a press

- …specifically checking for lockout/tagout devices

- …specifically checking the area around the press for safe conditions

- …specifically checking to ensure proper shields are installed and working properly

- …specifically checking over the job packet with the supervisor

- …specifically turning on the power at the power disconnect

- …specifically checking selector switch settings…motor forward selected

- …specifically testing the emergency stop circuit

- …specifically starting the motor

- …specifically checking the shield interlocks

- …specifically checking the jamb block interlock

- …specifically testing the anti tie-down circuit

- …specifically checking/testing the light curtain

- …specifically checking the brake monitor indicator

- IDENTIFY JOG, SINGLE STROKE AND CONTINUOUS MODE PRESSES

-

Senior Tool Maker

- BUILD SINGLE HIT, PROGRESSIVE, TRANSFER TOOLS,EQUIPMENT & PRODUCTION GAGES

- BUILD JIGS

- BUILD FIXTURES

- BUILD SPECIAL MACHINERY AS NECESSARY

- PERFORM FIRST PIECE APPROVAL OF TOOLS AND SPECIAL MACHINERY

- STAND FOR EXTENDED PERIODS OF TIME

- REMAIN ALERT FOR AN ENTIRE SHIFT

- HAVE GOOD FINGER AND HAND DEXTERITY

- PERFORM REPETITIVE TASKS

- PURCHASE & MAINTAIN PERSONAL TOOLS

- REPORT TO TOOLROOM MANAGER

- DE-BUG & TROUBLESHOOT TOOLS & SPECIAL MACHINERY

- PROGRAM CNC EQUIPMENT

- ATTEND & SUPPORT ALL MEETINGS & FUNCTIONS NECESSARY TO SUPPORT THE

- OPERATIONS OF OMNI MFG., INC.

- WORK IN EXTREME TEMPERATURES

- SUPERVISE JUNIOR TOOLMAKERS & APPRENTICES AS NECESSARY

-

Automation/IT Support

- PERFORM ELECTRICAL TROUBLESHOOTING AND REPAIR

- PERFORM ELECTRICAL/3 PHASE TROUBLESHOOTING AND REPAIR

- PERFORM GENERAL MACHINE EQUIPMENT REPAIR

- PERFORM GENERAL BUILDING MAINTENANCE

- POSESS GREAT FAMILIARITY WITH DIFFERENT TYPES OF PRESSES

- HAVE ABILITY TO SERVICE AND REPAIR MANY DIFFERENT TYPES OF PRESSES

- POSESS BASIC FABRICATION SKILLS

- POSESS A MIN OF 4 YRS EXPERIENCE PERFORMNG DUTIES IN AN INDUSTRIAL ENV,

- PERFORM BUTTON CHECKS

- PERFORM WORK AREA SAFETY CHECKS

- PERFORM STOP TIME DISTANCE PROCEDURES

- IDENTIFY SAFETY GUARDS - SHIELDING, SAFETY INTERLOCK, LIGHT CURTAINS

- IDENTIFY LOCKOUT/TAGOUT

- IDENTIFY EMERGENCY STOP BUTTONS

- IDENTIFY USE JAM BLOCK

- POSESS A BACKGROUND IN ELECTRICAL, GENERAL MECHANICAL, EQUIPMENT, PRESS

- TROUBLESHOOTING AND REPAIR AND BASIC FABRICATION

- POSESS STRONG VISUAL ACCUITY AND ACCURACY

- OPERATE WELDERS

- OPERATE PUNCH PRESS

- OPERATE SAWS

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- MAINTAIN MAINTENANCE DOCUMENTATION AND RECORDS

- HAVE ABILITY TO FOLLOW INSTRUCTIONS

- ASSUME MANY DIFFERENT ELEVATED WORKING POSITIONS

- HAVE PATIENCE AND TACT WHEN DEALING WITH OUTSIDE PATRONS, VENDORS, AND FELLOW EMPLOYEES

- WORK IN EXTREME TEMPERATURES

- WORK IN GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- HAVE ABILITY TO READ BLUEPRINTS AND PROCESS DRAWINGS

- HAVE ABILITY TO CREATE BLUEPRINTS AND ORGANIZE RECORDS/DRAWINGS

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- ADHERE TO ALL OMNI MANUFACTURING, INC. POLICIES

- COMPLETE TASKS UNDER DEADLINES

- POSESS STRONG COMMUNICATION AND TEAMWORK SKILLS

- IS ABLE TO REPAIR AND TEST ALL CHECK FIXTURES, CAMERAS, INSPECTION EQUIPMENT

- HAVE ABILITY TO WORK WITH ROCKEWLL CONTROLS

- HAVE ABILITY TO WORK WITH SIEMENS CONTROLS

- KNOWLEDGE OF PHONE SYSTEMS

- KNOWLEDGE OF SERVERS

- KNOWLEDGE OF OUR COMPUTER BACKUP PROCEDURES

- HAVE BASIC COMPUTER SKILLS, BE ABLE TO RESTORE PC's, VM's

-

Supervisor

- PERFORM ELECTRICAL TROUBLESHOOTING AND REPAIR

- PERFORM ELECTRICAL/3 PHASE TROUBLESHOOTING AND REPAIR

- PERFORM GENERAL MACHINE EQUIPMENT REPAIR

- PERFORM GENERAL BUILDING MAINTENANCE

- POSESS GREAT FAMILIARITY WITH DIFFERENT TYPES OF PRESSES

- HAVE ABILITY TO SERVICE AND REPAIR MANY DIFFERENT TYPES OF PRESSES

- POSESS BASIC FABRICATION SKILLS

- POSESS A MIN OF 4 YRS EXPERIENCE PERFORMNG DUTIES IN AN INDUSTRIAL ENV,

- PERFORM BUTTON CHECKS

- PERFORM WORK AREA SAFETY CHECKS

- PERFORM STOP TIME DISTANCE PROCEDURES

- IDENTIFY SAFETY GUARDS - SHIELDING, SAFETY INTERLOCK, LIGHT CURTAINS

- IDENTIFY LOCKOUT/TAGOUT

- IDENTIFY EMERGENCY STOP BUTTONS

- IDENTIFY USE JAM BLOCK

- POSESS A BACKGROUND IN ELECTRICAL, GENERAL MECHANICAL, EQUIPMENT, PRESS

- TROUBLESHOOTING AND REPAIR AND BASIC FABRICATION

- POSESS STRONG VISUAL ACCUITY AND ACCURACY

- OPERATE WELDERS

- OPERATE PUNCH PRESS

- OPERATE SAWS

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- MAINTAIN MAINTENANCE DOCUMENTATION AND RECORDS

- HAVE ABILITY TO FOLLOW INSTRUCTIONS

- ASSUME MANY DIFFERENT ELEVATED WORKING POSITIONS

- HAVE PATIENCE AND TACT WHEN DEALING WITH OUTSIDE PATRONS, VENDORS, AND FELLOW EMPLOYEES

- WORK IN EXTREME TEMPERATURES

- WORK IN GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- HAVE ABILITY TO READ BLUEPRINTS AND PROCESS DRAWINGS

- HAVE ABILITY TO CREATE BLUEPRINTS AND ORGANIZE RECORDS/DRAWINGS

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- ADHERE TO ALL OMNI MANUFACTURING, INC. POLICIES

- COMPLETE TASKS UNDER DEADLINES

- POSESS STRONG COMMUNICATION AND TEAMWORK SKILLS

- IS ABLE TO REPAIR AND TEST ALL CHECK FIXTURES, CAMERAS, INSPECTION EQUIPMENT

- HAVE ABILITY TO WORK WITH ROCKEWLL CONTROLS

- HAVE ABILITY TO WORK WITH SIEMENS CONTROLS

- KNOWLEDGE OF PHONE SYSTEMS

- KNOWLEDGE OF SERVERS

- KNOWLEDGE OF OUR COMPUTER BACKUP PROCEDURES

- HAVE BASIC COMPUTER SKILLS, BE ABLE TO RESTORE PC's, VM's

-

Material Handler

- PERFORM ELECTRICAL TROUBLESHOOTING AND REPAIR

- PERFORM ELECTRICAL/3 PHASE TROUBLESHOOTING AND REPAIR

- PERFORM GENERAL MACHINE EQUIPMENT REPAIR

- PERFORM GENERAL BUILDING MAINTENANCE

- POSESS GREAT FAMILIARITY WITH DIFFERENT TYPES OF PRESSES

- HAVE ABILITY TO SERVICE AND REPAIR MANY DIFFERENT TYPES OF PRESSES

- POSESS BASIC FABRICATION SKILLS

- POSESS A MIN OF 4 YRS EXPERIENCE PERFORMNG DUTIES IN AN INDUSTRIAL ENV,

- PERFORM BUTTON CHECKS

- PERFORM WORK AREA SAFETY CHECKS

- PERFORM STOP TIME DISTANCE PROCEDURES

- IDENTIFY SAFETY GUARDS - SHIELDING, SAFETY INTERLOCK, LIGHT CURTAINS

- IDENTIFY LOCKOUT/TAGOUT

- IDENTIFY EMERGENCY STOP BUTTONS

- IDENTIFY USE JAM BLOCK

- POSESS A BACKGROUND IN ELECTRICAL, GENERAL MECHANICAL, EQUIPMENT, PRESS

- TROUBLESHOOTING AND REPAIR AND BASIC FABRICATION

- POSESS STRONG VISUAL ACCUITY AND ACCURACY

- OPERATE WELDERS

- OPERATE PUNCH PRESS

- OPERATE SAWS

- MAINTAIN HOUSEKEEPING IN HIS/HER WORK AREA

- MAINTAIN MAINTENANCE DOCUMENTATION AND RECORDS

- HAVE ABILITY TO FOLLOW INSTRUCTIONS

- ASSUME MANY DIFFERENT ELEVATED WORKING POSITIONS

- HAVE PATIENCE AND TACT WHEN DEALING WITH OUTSIDE PATRONS, VENDORS, AND FELLOW EMPLOYEES

- WORK IN EXTREME TEMPERATURES

- WORK IN GREASY OR DIRTY ENVIRONMENT

- WORK IN A LOUD ENVIRONMENT

- HAVE ABILITY TO READ BLUEPRINTS AND PROCESS DRAWINGS

- HAVE ABILITY TO CREATE BLUEPRINTS AND ORGANIZE RECORDS/DRAWINGS

- UNDERSTAND HOW TO USE BARCODE SYSTEM/TERMINAL OPERATION

- ADHERE TO ALL OMNI MANUFACTURING, INC. POLICIES

- COMPLETE TASKS UNDER DEADLINES

- POSESS STRONG COMMUNICATION AND TEAMWORK SKILLS

- IS ABLE TO REPAIR AND TEST ALL CHECK FIXTURES, CAMERAS, INSPECTION EQUIPMENT

- HAVE ABILITY TO WORK WITH ROCKEWLL CONTROLS

- HAVE ABILITY TO WORK WITH SIEMENS CONTROLS

- KNOWLEDGE OF PHONE SYSTEMS

- KNOWLEDGE OF SERVERS

- KNOWLEDGE OF OUR COMPUTER BACKUP PROCEDURES

- HAVE BASIC COMPUTER SKILLS, BE ABLE TO RESTORE PC's, VM's

Our Capabilities

Stamping

Omni’s production facility houses over 75 metal stamping presses and the necessary support equipment. Our presses range in size from 50 tons to 1500 tons.

Welding

We have numerous robotic weld cells, each capable of handling multiple weld operations in a production environment.

Tool Room

Our experienced tool makers have the expertise you need for your next project. Call us today to find out how we can help take your idea to reality.