Stamping

Stamping

Omni’s production facility houses over 50 metal stamping presses and the necessary support equipment to keep our lines running like you've come to expect. Our presses range in size from 50 to 1500 tons, and feature various sizes and speeds, allowing us to run a vast array of tooling. Our presses are on an intense service and maintenance program to minimize downtime. Die protection and/or automation are easily implemented with our modern press controls. All our process equipment is also located within our facility thus ensuring that material handling is also minimal.

With such an assortment of equipment and tooling capabilities, Omni’s production center can do most standard operations associated with metal stamping, and some rather unique operations, as well. Cut-off, punching, coining, drawing, in-die tapping, forming, and roll forming are but a few of the operations that may be performed at any given time. Combining these operations within one tool is common to make some rather sophisticated parts. Parts that can’t be run in a progressive tool are often adapted to an automated transfer system to help us remain competitive.

Omni operates with modern production control and the entire facility operates with wireless automatic data collection (ADC). This system contributes largely to our ability to consistently process over 300 tons of steel each month and maintain an accurate inventory.

Omni maintains a fully qualified staff of managers, production associates, and set-up personnel. Our maintenance personnel are able to make most repairs to equipment, even major failures, keeping us relatively independent from outside support services. Everyone at Omni is trained in safe working habits. A safe working atmosphere becomes apparent as soon as you enter our facility.

Our Capabilities

Stamping

Omni’s production facility houses over 75 metal stamping presses and the necessary support equipment. Our presses range in size from 50 tons to 1500 tons.

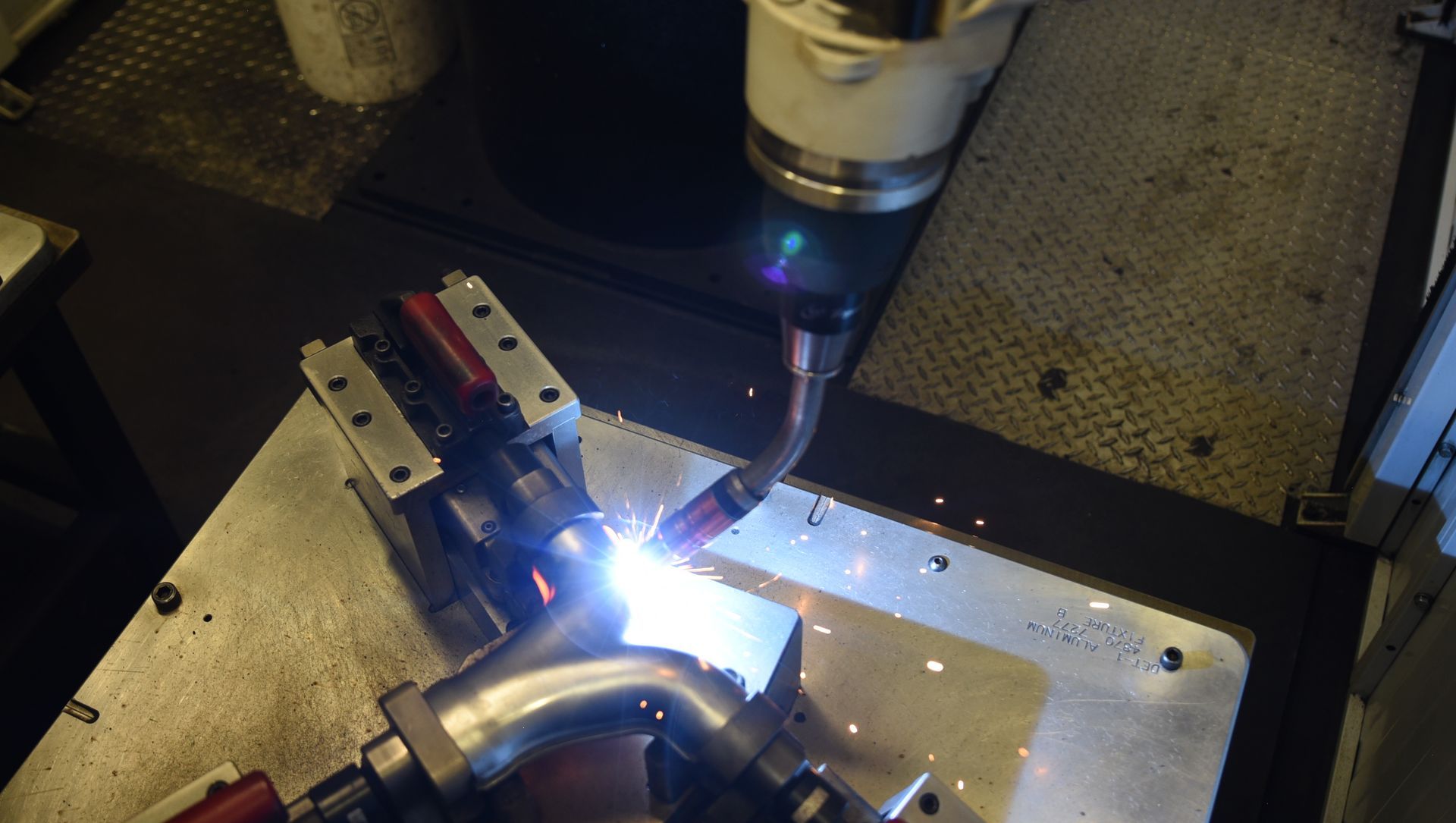

Welding

We have numerous robotic weld cells, each capable of handling multiple weld operations in a production environment.